1. Introduction

The USB Type-C standard has been developed to meet

the ever growing needs of connectivity between modern devices. USB Type-C

connectivity provides both power and data exchange at higher power levels

and higher speeds compared to the legacy USB standard. The mechanical design

of the USB Type-C connector and receptacle has also been improved, to enable

smaller form factor and make the connection more user-friendly.

Table 1 below shows a comparison between the older

USB and new USB Type-C standard :

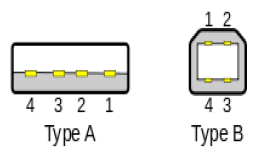

|

Connector

Picture

|

Connections

|

Data Speed

|

Voltage/Current

|

|

USB 1.x/2.0

standard

|

1 = VBUS, 4 = GND

3 = Data+, 2 = Data-

|

USB 1.0/1.1 :

Low speed : 1.5Mbps

Full speed : 12Mbps

USB 2.0 :

High speed : 480Mbps

|

5V/500mA

BC1.2 : 5V/1.5A

(for charging systems)

|

|

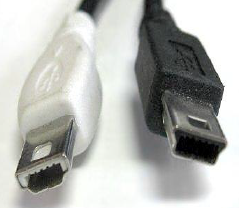

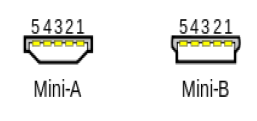

USB 1.x/2.0 Mini

|

1 = VBUS, 5 = GND

3 = Data+, 2 = Data-

4 = ID pin :

Host = GND, device = float

|

|

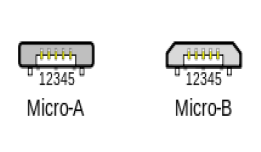

USB 1.x/2.0

Micro

|

1 = VBUS, 5 = GND

3 = Data+, 2 = Data-

4 = ID pin :

Host = GND, device = float

|

|

USB 3.0

|

1 = VBUS, 5, 8 = GND

2 = Data-, 3 = Data+

4 = USB-OTG,

6 = Tx-, 7 = Tx+, 9 = Rx-, 10 = Rx+

|

USB 3.0 :

Super speed: 5Gbps

|

5V/900mA

|

|

USB Type-C :

Smaller physical size

Reversible plug

Higher voltage & current

Auto-configurable

Highest data speed

|

Receptacle :

Plug:

Legacy Data-, Data+

Two pairs of Rx1/2 and Tx1/2

CC1/2 for configuration

VCONN (active cable power)

SBU 1/2 for sideband/audio

|

USB 2.0 :

High speed : 480Mbps

USB 3.0 :

Super speed : 5Gbps

USB 3.1 :

Super speed+ : 10Gbps

|

Default : 5V / 1.5A

5V/3A max

USB PD :

5V to 20V, 5A max

USB PD 3.0 with PPS

3V to 20V, 5A max

|

Table 1

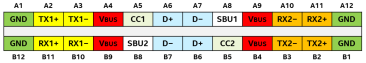

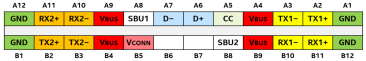

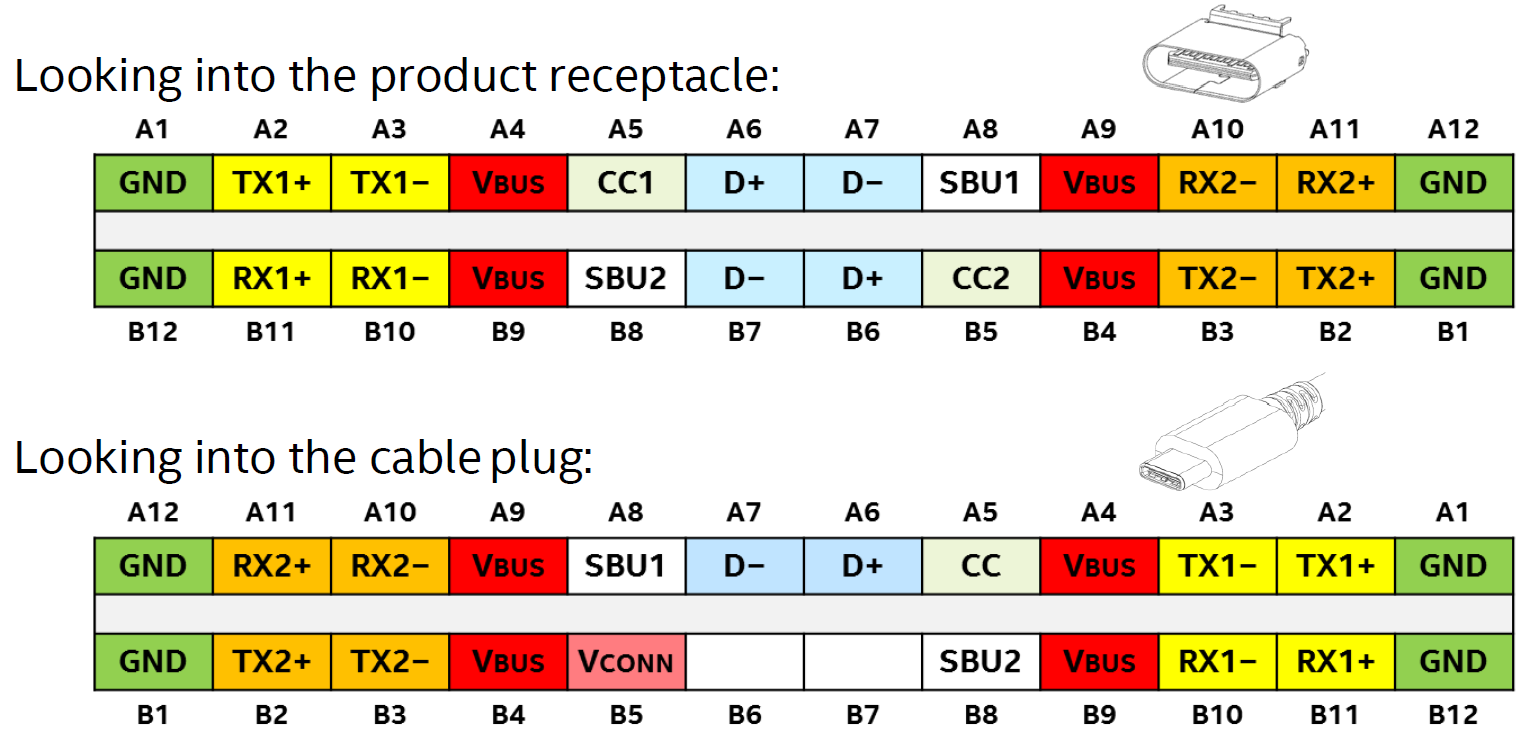

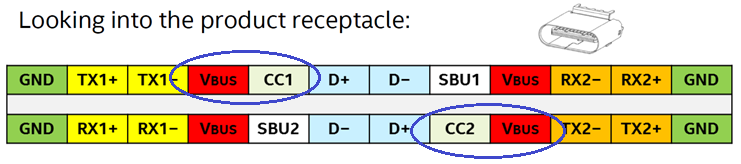

From Table 1 it can be seen that the new USB Type-C

standard has several important advantages :

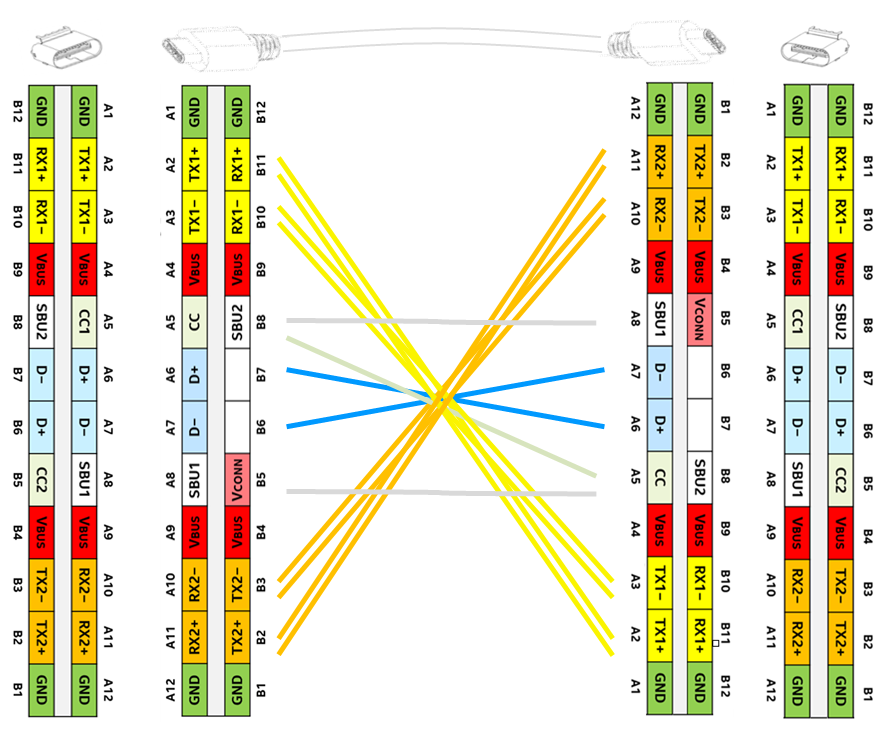

- USB Type-C plug is reversible, so it can be plugged in either way;

the pinning is laid out in such a way that power connections will always

meet correctly. Since the receptacle has two rows of D+ and D- where the

two D+ lines and the two D- lines are connected together so the D+ and

D- will always meet-up. The high speed TX lines and RX lines cannot be

connected together. Therefore the USB Type-C CC lines are used to

identify the cable orientation and will configure the TX/RX hardware to

work correctly.

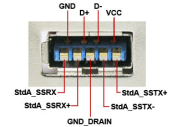

Figure 1 : USB Type-C receptacle and cable plug

pinning.

Figure 1

- Another difference between older USB standards and the new USB Type-C

standard is the dual role capability : USB Type-C cables have identical

plugs on either side of the cable, which means that devices connected

together have to tell each other who will be acting as host and who will

be acting as device. Note that these roles need to be determined for

both data and power after connection of the cable: For data

transmission, the host is called the Downstream Facing Port (DFP) and

the device is called the Upstream Facing Port (UFP). For power, the

power provider is the Source and power consumer is the Sink. Some

applications can have Dual Roles for Data (DRD) and Dual Role for Power

(DRP). The CC lines will be used to define the power role of the two

connected devices during connection.

- Another advantage of the USB Type-C system is its higher power

capability. Whereas the legacy USB was able to provide 2.5W only, USB

Type-C is able to provide up to 5V/3A, 15W max, and with Power Delivery,

the voltage & current range is increased to 20V/5A for maximum power of

100W. This makes it possible to power larger devices from the USB PD

port, like monitors, and also allows charging devices with large battery

packs like notebook computers. The new USB PD 3.0 standard also supports

Programmable Power Supply (PPS) which allows fine adjustment of the bus

voltage and current, and even allows lower voltage than 5V; PPS VBUS can

be adjusted down to 3V which is very useful in Direct Charge systems

where the Bus voltage is directly connected to the battery for highest

efficiency charging. Standard type-C cables are rated for currents up to

3A. For higher currents up to 5A, special E-marked cables need to be

used. These cables include a Cable ID IC that indentifies the cables

capability via the CC line. E-mark ICs require a 5V power supply to be

applied to the cable VCONN pin via one of the CC wires.

- The Super Speed + 10Gbps data rate via the TX/RX pairs makes it

possible to transfer signals that previously needed dedicated cables,

like HDMI/DisplayPort/Thunderbolt, and allows 4k video to be transferred

over USB Type-C. HDMI signal transfer via USB Type-C cables requires

special use of the data transfer pairs in the cable, which is called

Alternate Mode.

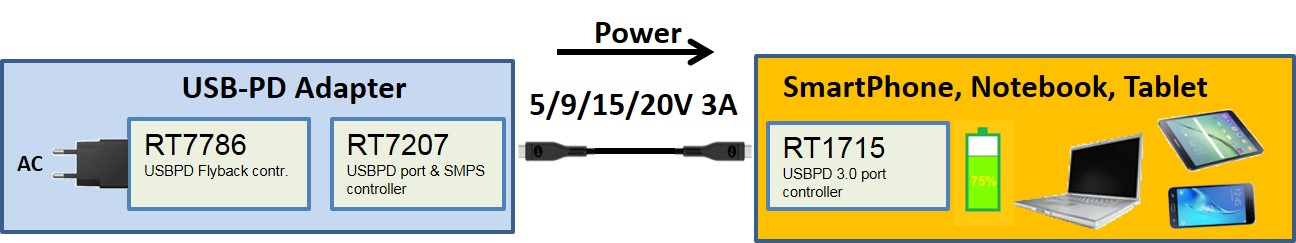

Below figures show some examples of USB Type-C

applications and related Richtek power management ICs :

Figure 2.

Figure 2 shows a typical USB-PD adapter charging

solution, where the adapter power supply provides an adjustable USB bus

voltage 5V, 9V, 15V or 20V based on the request of the device attached.

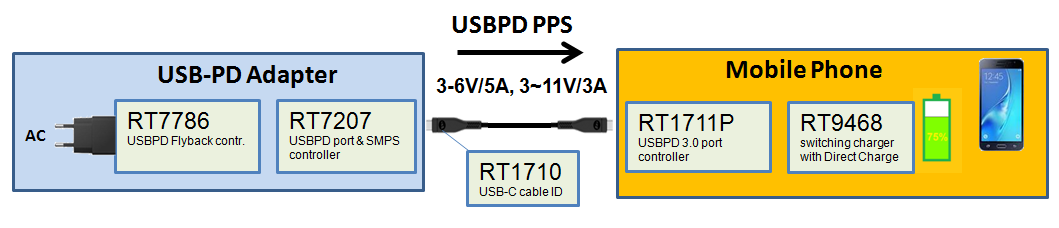

Figure 3

Figure 3 is a similar application as Figure 2, but now

utilizing the USBPD 3.0 Programmable Power Supply function to fine-adjust

the bus voltage over a wider voltage range. The extended VBUS low voltage

range down to 3V makes it possible to use the Direct Charge concept, which

connects the VBUS directly to the battery and controls the battery charge

current and voltage via the USB PD 3.0 communication protocol.

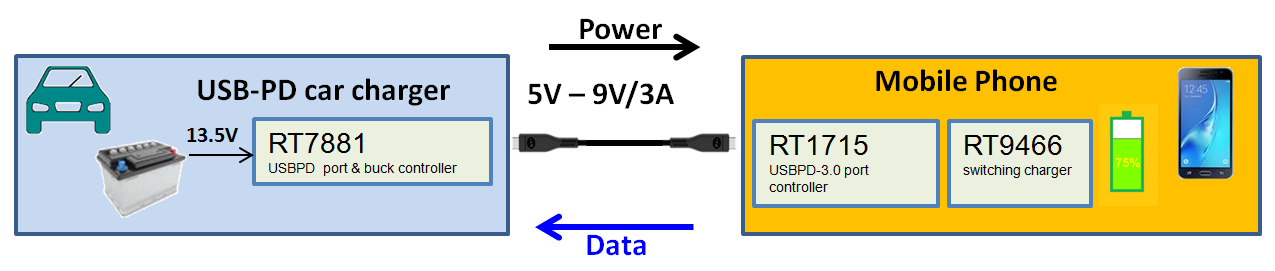

Figure 4

Figure 4 shows a car charger application where the car

battery voltage is stepped down to 5V or 9V based on the request of the

battery charger in the mobile phone. The mobile phone can provide data (like

audio) to the car infotainment system.

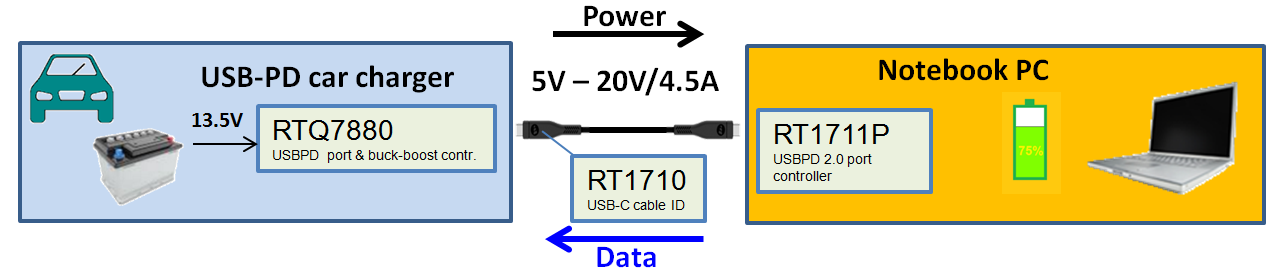

Figure 5

To charge larger devices like notebook computers from

the car battery, higher bus voltage is needed. Figure 5 shows a 90W car

charging solution which makes use of a buck-boost converter. Again the

notebook computer will request a suitable BUS voltage via the USB-PD

protocol. The higher 4.5A cable current will require the use of an active

cable with E-mark IC.

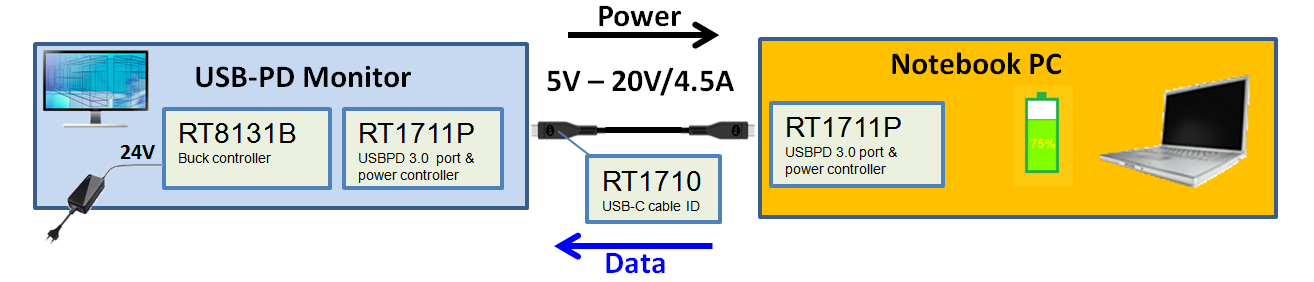

Figure 6

Computer Displays with USB Power Delivery can act as

power source as is shown in Figure 6 where a USB-PD monitor provides power

to the Notebook computer while receiving display data over the same USB

cable in Alternate Mode.

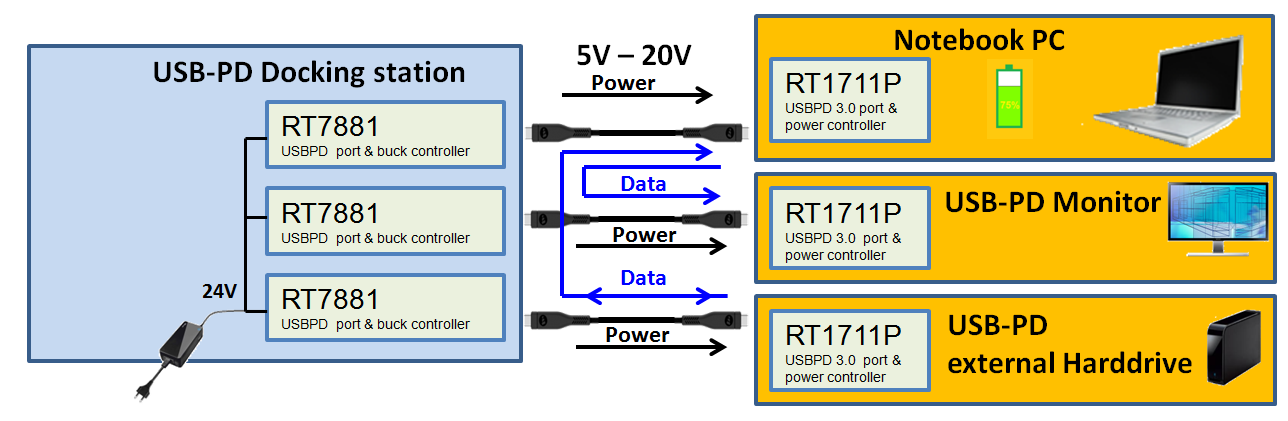

Figure 7

Figure 7 shows a powered docking station which can

connect to several devices, delivering power and routing data streams

between the devices.

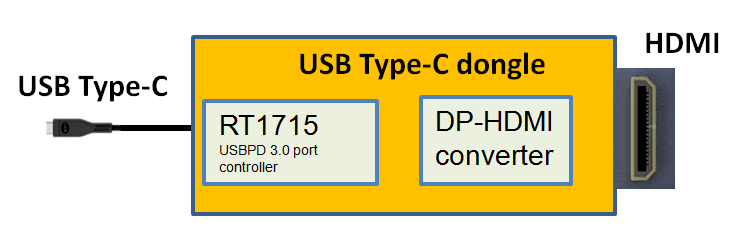

Figure 8

With the introduction of USB Type-C, there is a need

to be able to connect other interfaces to this port.

Figure 8 shows a USB Type-C to HDMI converter cable.

The bus voltage will stay at 5V, and the converter electronics are powered

from the bus voltage.

2. How USB Type-C configures data and power

Data transfer

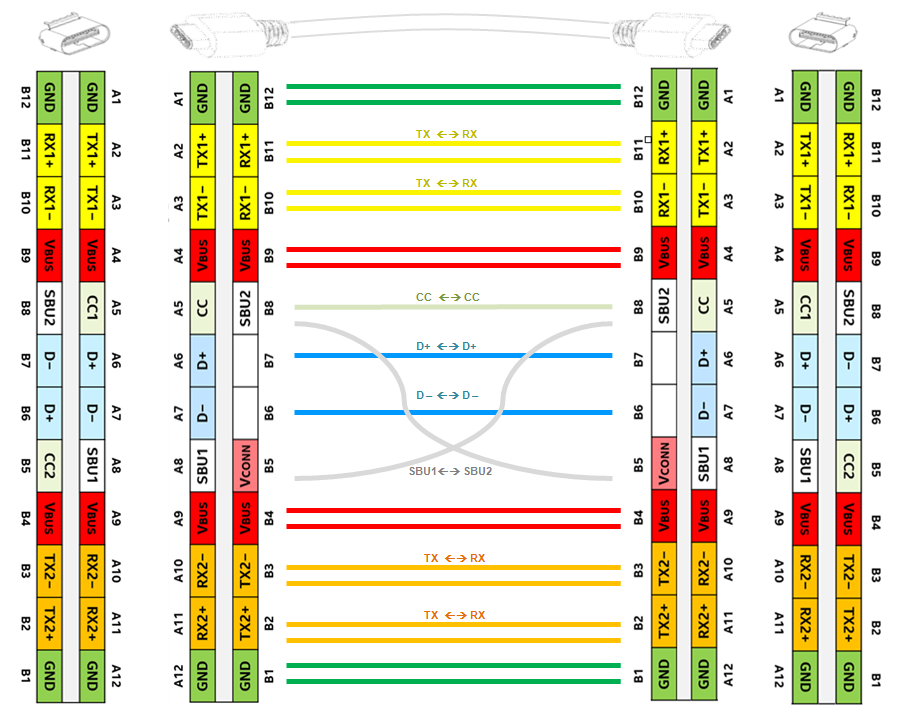

Figure 9 : non-twisted, non-flipped straight

connection.

Figure 9 shows a non-twisted cable with un-flipped

connector –receptacle position.

From left receptacle to right receptacle, the

RX1pair connects to TX1 pair and Rx2 pair connects to TX2 pair.

D+ connects to D+ and D- connects to D-. SBU1

connects to SBU2. CC1 connects via CC wire to CC1.

USB-3.1 uses only two data pairs. In this case, the

high speed data travels via RX1+/- and TX1+/- from one side to the other

side.

Note that VCONN is not wired through; the VCONN

voltage for powering cable E-mark ICs is only provided from one side, after

determining whether a cable includes an E-mark IC or not.

Figure 10 : twisted cable connection

Figure 10 shows a twisted cable connection with

receptacle in same position.

In this condition, from left receptacle to right

receptacle, the RX1 pair connects to TX2 pair and Rx2 pair connects to TX1

pair. D+ still connects to D+ and D- still connects to D-. SBU1 connects to

SBU1, SBU2 to SBU2. CC1 connects via CC wire to CC2. High speed data now

needs to travel from RX1+/- and TX1+/- left to RX2+/- and TX2+/- on the

right. It means the data transceiver needs to switch to different data

pairs.

There are totally 4 connection possibilities:

flipped or non flipped receptacle and twisted or non twisted cable.

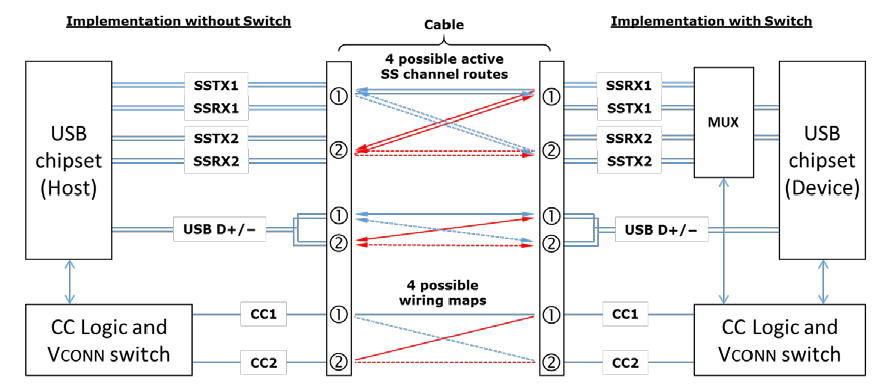

In USB 3.1 systems, the RX/TX data-lines require a

multiplexer to correctly reconfigure the RX/TX lines in all possible cable

orientations. Figure 11 shows the data bus routing possibilities between to

USB Type-C ports. The cable / receptacle orientations are detected via the

CC1/CC2 pins on either side. The CC (Channel Configuration) logic controller

will set the multiplexer function accordingly. This can be done either via a

multiplexer switch or data line selection embedded in the USB chipset.

Figure 11

Power transfer

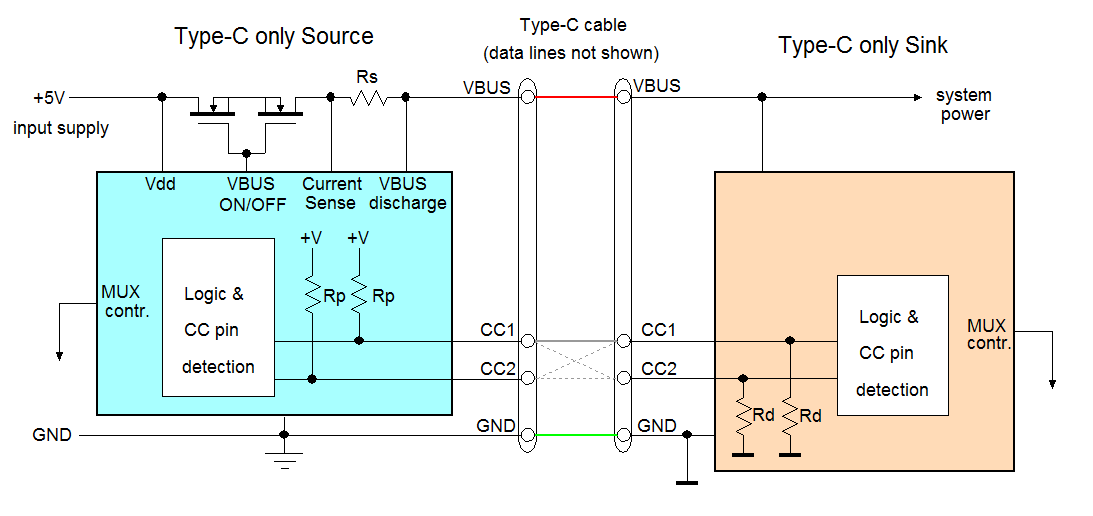

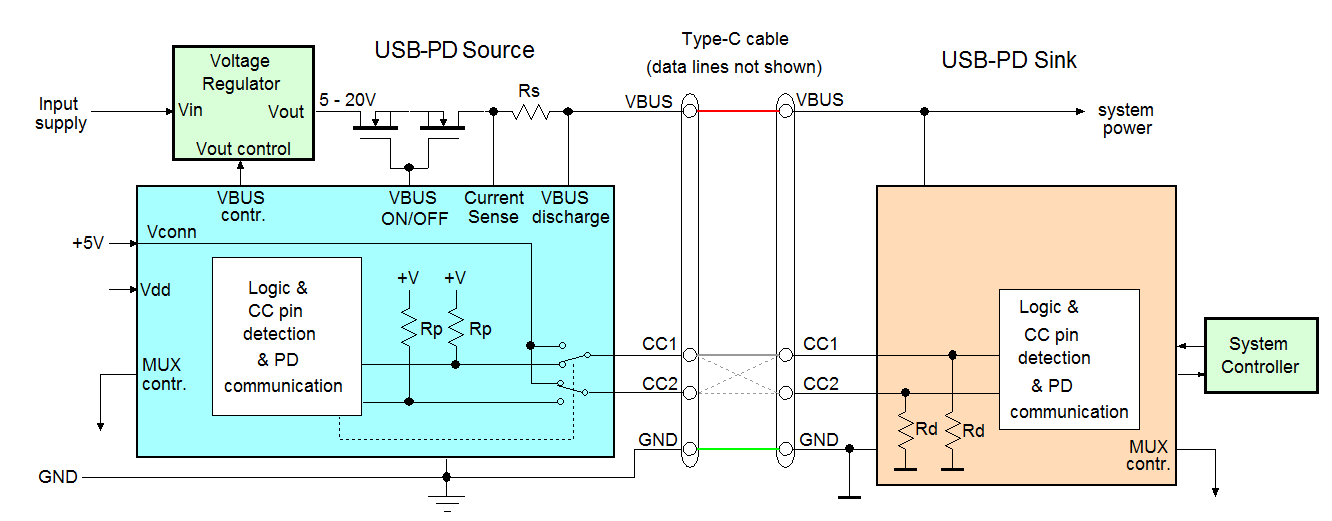

The basic USB Type-C Source to Sink without Power

Delivery block diagram is shown in Figure 12.

Figure 12

A USB Type-C source will always include a MOSFET

switch for enabling/disabling the VBUS voltage. It can also include a VBUS

current sense, to check for over-current conditions, and a VBUS discharge

function. Both Source and Sink will include a CC1/CC2 line detection

circuit.

The CC (Channel Configuration) lines are used to

establish power exchange between the two applications connected together.

Initially, the USB Type-C VBUS line will be unpowered. During the cable

connection the power role of each application needs to be defined. It is

defined that the power provider (source) will pull-up the CC lines at the

receptacle and the power consumer will pull down the CC lines at the

receptacle.

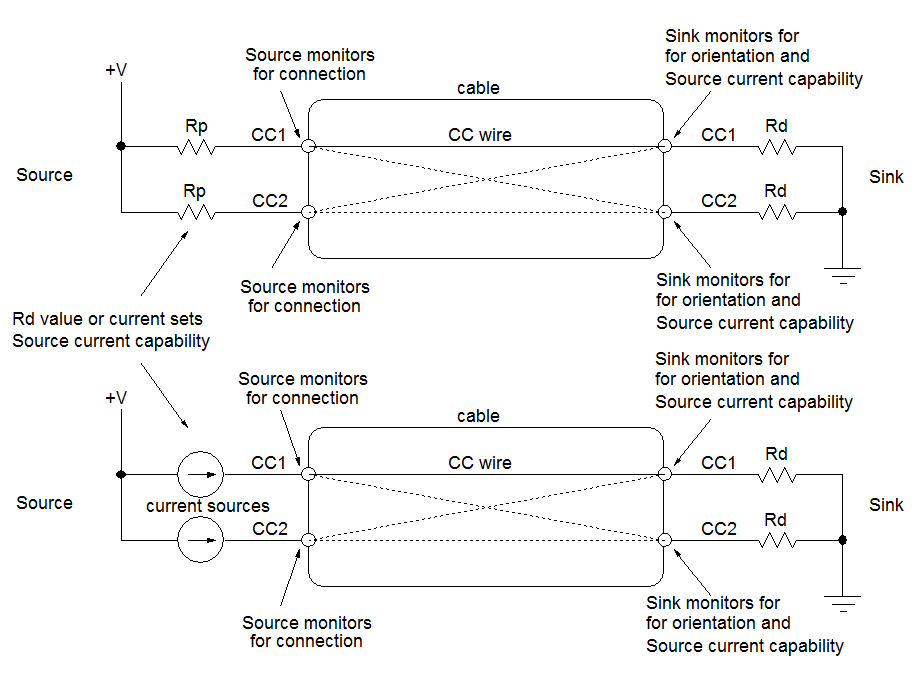

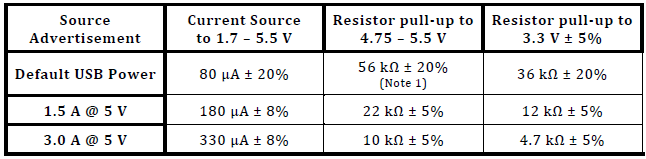

Figure 13

Figure 13 shows the method for establishing power

role, cable orientation and current capability: Source pulls up CC1 and CC2

with resistor Rp. It monitors the CC1/CC2 lines, which will be high when

nothing is connected. As soon as Sink is connected, it pulls the CC1 and CC2

lines down with resistor Rd. Since there is only one CC line in the cable,

the Source will see either CC1 or CC2 voltage dropping. The Sink also checks

the CC1/CC2 lines and checks the voltage of the line that is pulled up. The

voltage level will tell the Sink how much current the Source is able to

deliver. It is also possible to use current sources instead of pull-up

resistor Rp, which is easier to implement in ICs and makes the application

less sensitive to V+ tolerance.

The Sink pull-down resistor Rd is defined to be

5.1kΩ. The CC line voltage is now defined by the Source pull-up resistor Rp

values (or current source values). These are defined for 3 different Bus

current capabilities : The lowest voltage on the CC line (around 0.41V)

means default USB power (current = 500mA for USB2.0 or 900mA in USB3.0). A

higher CC line voltage (around 0.92V) defines a current capability of 1.5A.

When the CC line voltage is around 1.68V, the maximum current capability is

defined at 3A. See Figure 14.

Figure 14

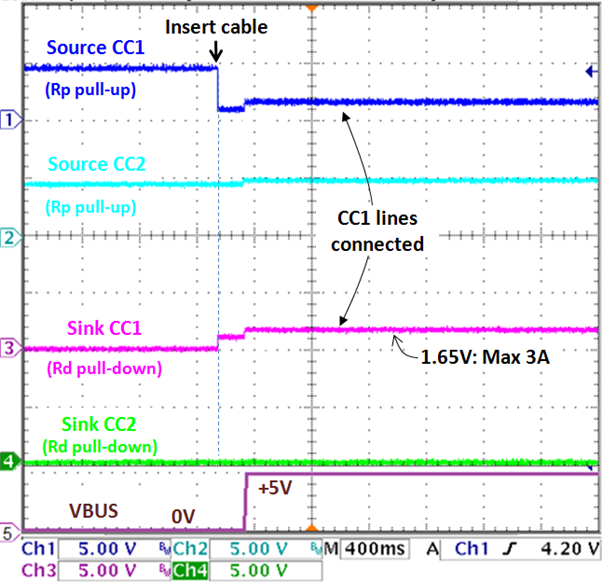

Figure 15 shows an example measurement where a power

provider (Source) is being connected to a power consumer (Sink) by means of

a normal USB Type-C cable.

|

Figure 15

|

Initially the CC1 & CC2 pins of the

Source receptacle are pulled up via the two Rp resistors, and

the CC1 & CC2 pins of the Sink are pulled down via the Rd

resistors.

When the cable is connected, it depends

on cable orientation which CC1/2 signals will line-up. In this

case the cable was not twisted, and CC1 at Source connects to

CC1 at Sink, so the CC1 line now shows a voltage determined by

the Rp/Rd resistor divider. The voltage level is read by the

Sink so it knows how much current the Source is able to provide.

In this example, the connected CC1 line

shows around 1.65V, which means the Source is able to provide

maximum 3A current.

The 5V Bus voltage is enabled after the

CC line connection has been verified.

In USB Type-C only without Power

Delivery systems, the Rp/Rd divider will determine the maximum

bus current that can be delivered, but the source can only

provide 5V.

|

USB Type-C systems with Power Delivery (PD) can

increase the bus voltage, from 5V up to 20V maximum. The communication

between Source and Sink regarding bus voltage and current is then done via

serial BMC code on the connected CC line.

The basic USB Type-C Source to Sink with Power

Delivery block diagram is shown in Figure 16.

Figure 16

The Source now includes a voltage regulator that is

controlled by the Source PD controller. Depending on the input voltage and

the maximum bus voltage requirements, this voltage regulator can be a buck,

boost or buck-boost or a flyback converter. The CC line PD communication is

handled by the PD controller as well. USB-PD systems also need to be able to

switch a VCONN supply to one of the CC lines. (see later section on eMark

ICs).

After cable connection has been established, devices

with Power Delivery (PD) function will start SOP communication via the

active CC line regarding power profile selection: The Sink will interrogate

the Source regarding available power profiles (different bus voltages and

currents). Because the Sink power requests are often related to the Sink

system (i.e. battery charger), it is often the Sink embedded system

controller (EC) that will first communicate with the Sink PD controller (via

I2C) for specific power requests.

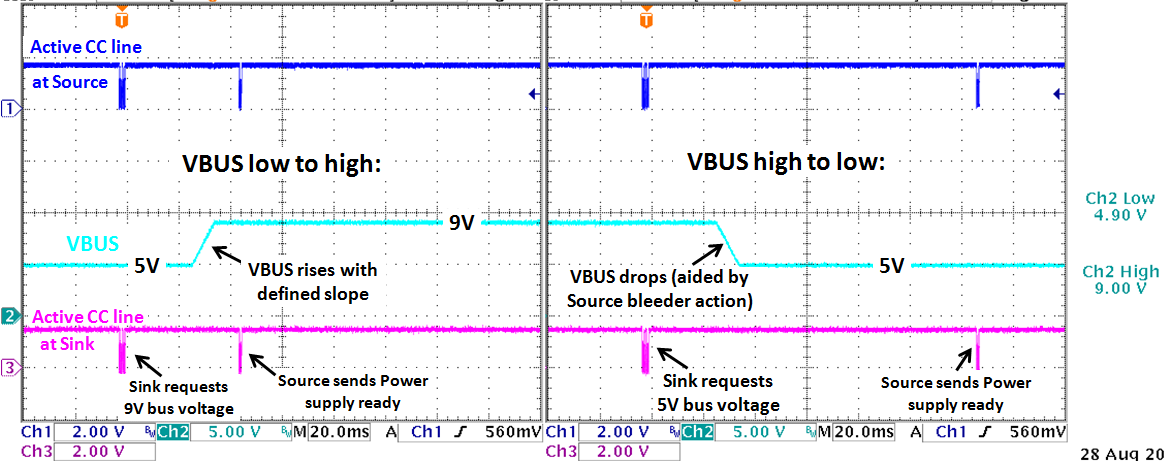

Figure 17 shows an example of a PD request where the

Sink requests a higher bus voltage.

Figure 17

The CC line communication between Sink and Source will

look like below :

1. The Sink will first request Source

capabilities.

2. The Source will provide its source

capabilities.

3. The Sink will then request a

suitable power profile from the Source capability list.

4. The Source will accept the request

and start to make changes to the BUS voltage. The Sink will minimize the bus

loading during BUS voltage change. The Source will increase the VBUS voltage

with a defined slew rate.

5. After the BUS voltage has reached its final

value, the source will wait until the BUS has stabilized and then will send

a Power Supply Ready signal. The Sink will now increase the BUS loading

again.

When the Sink wants to reduce the Bus voltage a similar

communication sequence will happen.

But during the VBUS reduction, the Source will also

activate a bleeder (VBUS discharge) to help reducing the bus voltage faster.

The Source will wait a bit longer for VBUS stabilizing and will

then send Power Supply ready signal.

This communication method ensures that any power change

on the BUS is always within capability of both Source and Sink. As soon as

the Type-C cable is disconnected, the BUS voltage is removed, and any new

connection will start with cable connection check and the lowest bus voltage

(5V). This will avoid any damage when plugging cables from one device into

another device.

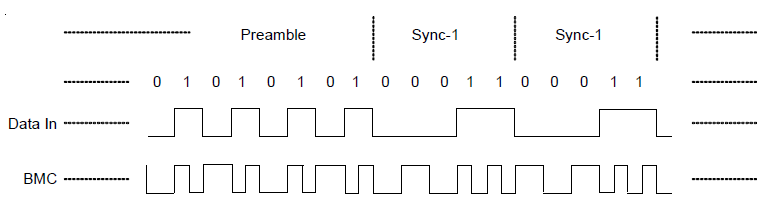

USB PD communication makes use of the Bi-phase Mark

Code (BMC). This code is a single wire communication, where a logic 1 is

transmitted by a hi-low change and a logic zero is transmitted as either a

fixed high level or a fixed low level. Each data packet consists of a

low-high-low sequence preamble, SOP (Start Of Packet), Header, message data

bytes, CRC error checking and EOP (End Of Packet). See Figure 18.

Figure 18

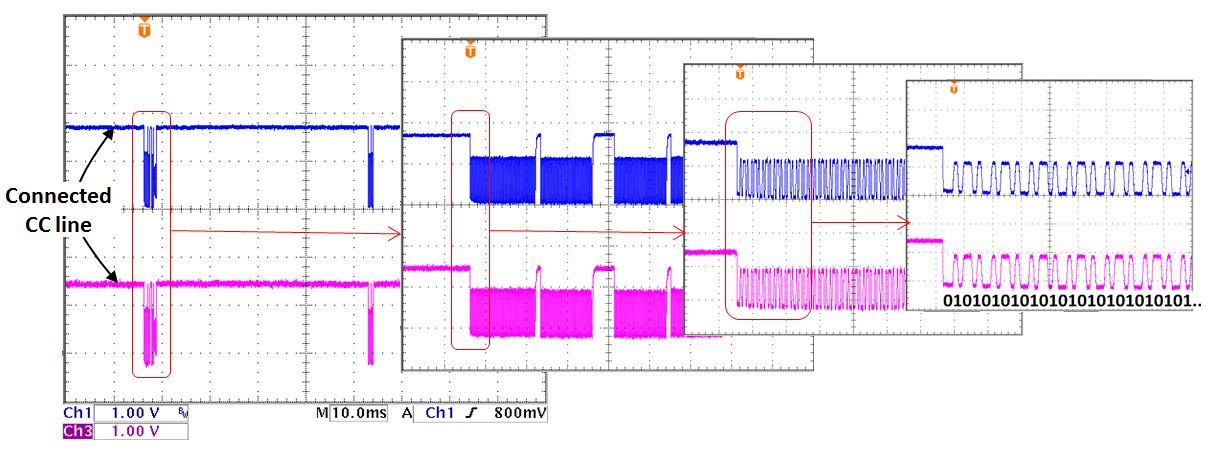

Just how dense the communication packets actually

are can be seen in Figure 19 which captured the PD communication after

requesting a VBUS voltage increase. The zoomed section shows the preamble

sequence.

Figure 19

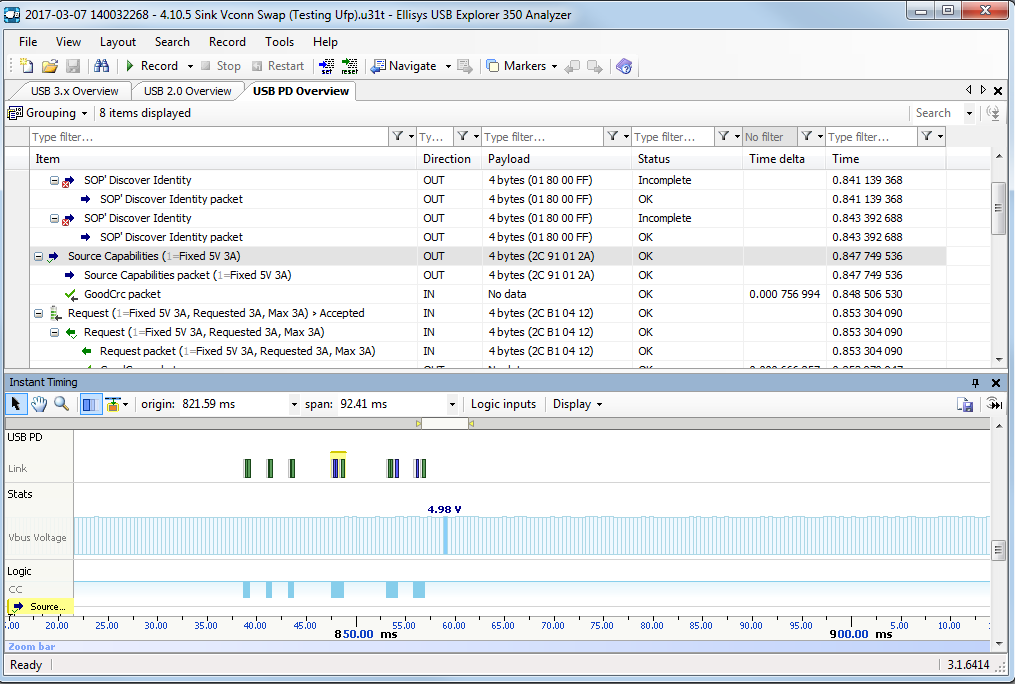

The BMC data can be decoded by USB PD decoders like

Ellisys EX350 Analyzer. These tools will capture PD data, show the meaning

of each packet, and show the timing related data with Vbus value, and CC

waveform. See Figure 20.

Figure 20

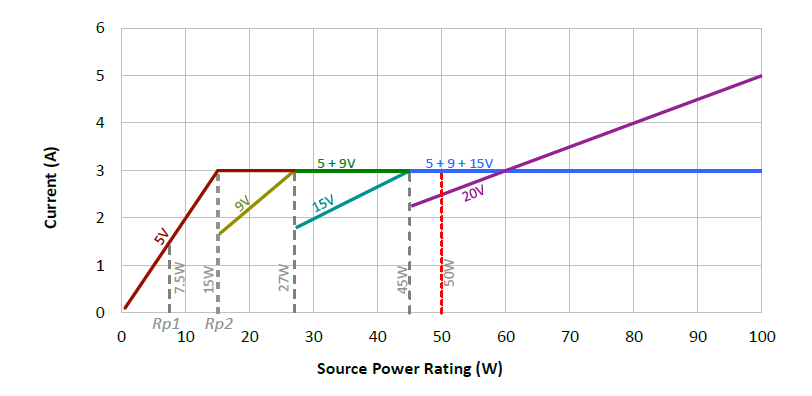

Power profiles

The USB PD 3.0 specification defines the following

power profiles :

Figure 21

Four different discrete voltage levels are defined :

5V, 9V, 15V and 20V. For the 5V, 9V and 15V, the maximum current is 3A. The

20V profile can be max 20V/3A (60W) for normal cables but it can be

increased to 20V/5A (100W) when using special e-marked cables. A system that

supports a certain maximum voltage / power level must support all lower

voltage / power levels as well.

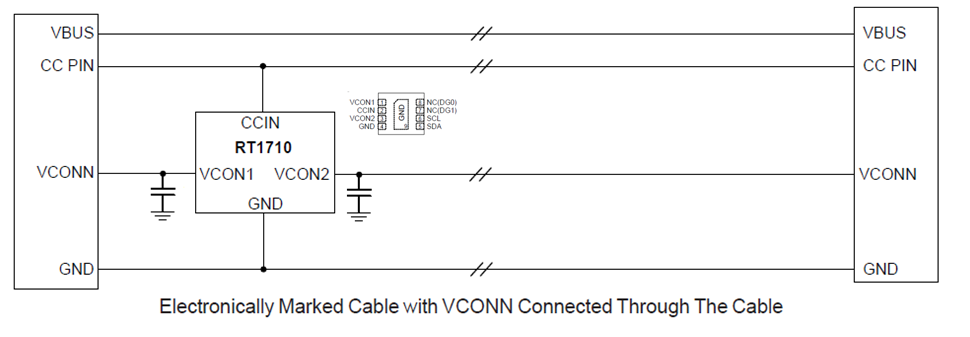

E-Marked cables

USB Type-C specifies various cables : For low speed

USB2.0 cables, there are no special requirements except that cable current

rating is 3A. Cables that support Superspeed USB3.1 data transfer or can

carry currents higher than 3A must be electronically marked. Figure 22 shows

the situation where the cable contains an IC that identifies the cable

characteristics (eMark IC). Active cables also can contain a re-driver IC

for signal conditioning. These ICs need to receive power from one of the

cable’s VCONN pins.

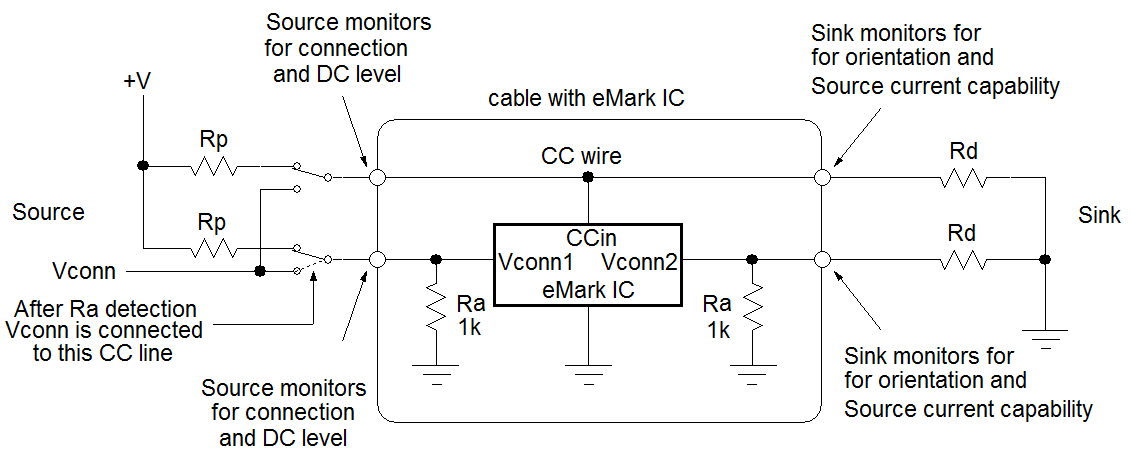

Figure 22

Cables with an eMark IC will have an internal 1k

pull-down resistor Ra on the VCONN pin, so Ra has a lower value than Rd

which is typically 5.1k. After inserting this type of cable, the Source will

see both CC1 and CC2 pin voltages dropping. The voltage levels will tell the

host which pin is pulled down by the Source via 5.1kΩ Rd resistor and which

pin is pulled down by the cable 1kΩ Ra resistor, so cable orientation can

still be determined. The Ra pull down action will also tell the Source that

a VCONN 5V power needs to be applied to that CC pin for powering the eMark

IC.

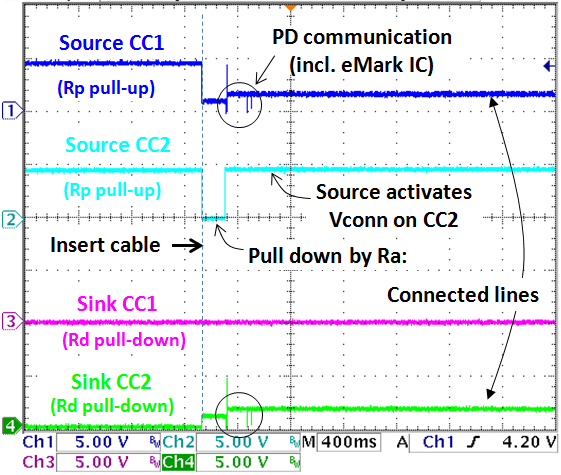

Figure 23 shows an example measurement where a power

provider (Source) is being connected to a power consumer (Sink) by means of

a cable with eMark IC. (In this case the cable was twisted)

|

Figure 23

|

It can now be seen that when the cable

is connected, one of the CC lines at the Source is now pulled

down to a very low level due to the low Ra value (1kΩ) on the

VCONN pin.

The Source will sense this and will know

that the cable contains an E-mark IC. It will then apply a 5V

VCONN supply to this CC line to power the cable internal

electronics.

PD communication will take place, which

now includes the data communication between Source and eMark IC

(called SOP’ or SOP’’) and the data communication between Source

and Sink (called SOP communication)

|

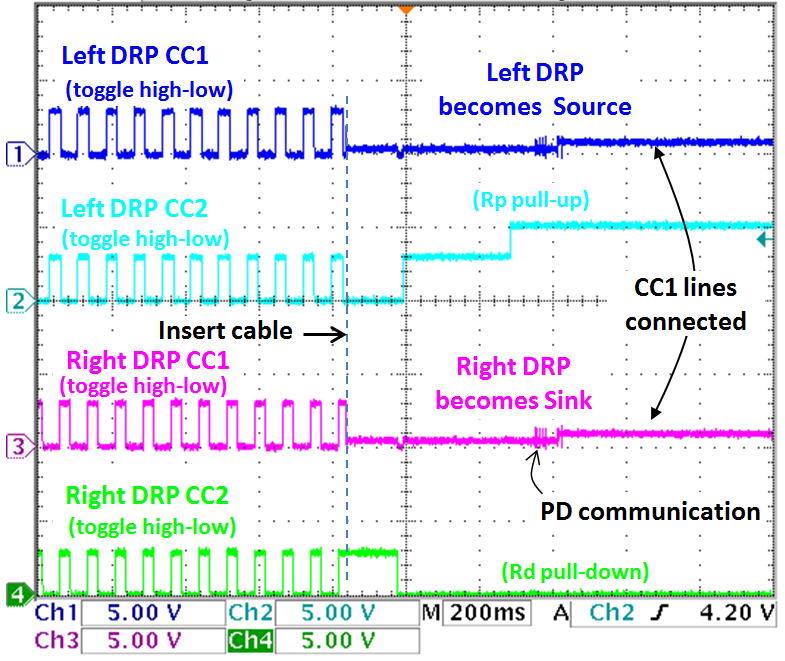

Dual Role for Power (DRP)

Some USB Type-C devices can act as Source and Sink,

the so called Dual Role for Power (DRP) devices. These devices will toggle

the CC1 and CC2 pins high-low before connection is made. If two DRP devices

are connected together, both end of the cable show toggling CC lines as is

shown in Figure 24.

Figure 24

In this connection event, the left DRP took the role

as Source and the right DRP became Sink. But it could also be vise versa,

unless one DRP has set a preference as Source (i.e. when it’s powered by an

external adapter) or preference as Sink (i.e. when it is powered by a

battery).

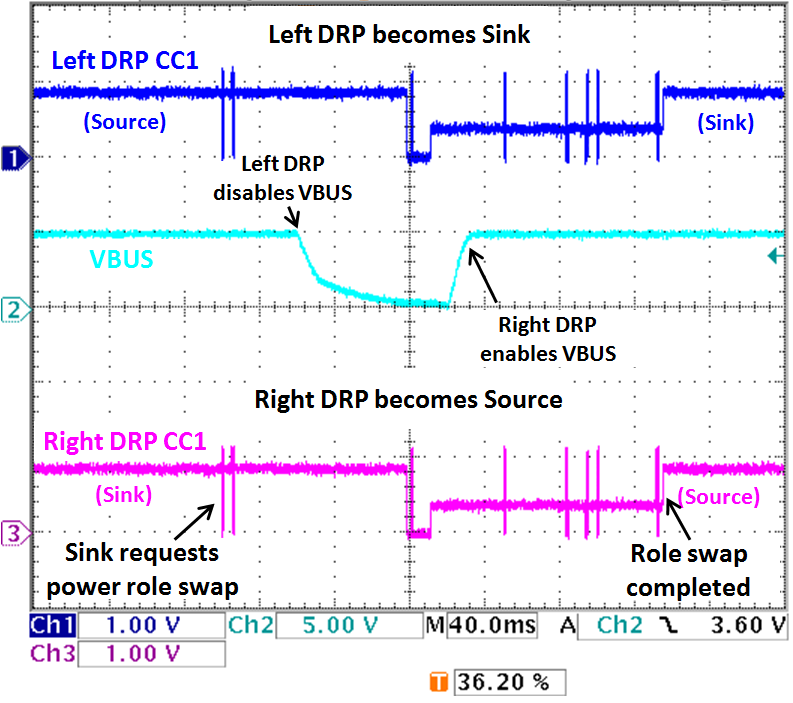

Power Role swapping can be done while connected:

When two DRP’s are connected together, either side can request a power role

swap. Figure 25 shows an example of Power Role Swap.

Figure 25

3. Introduction to Richtek USB Type-C PD solutions

Since the start of the USB Type-C PD specification

definition, Richtek has been a member of the USB Implementers Forum (USB-IF)

in order to stay updated with the latest developments of the standard.

Richtek has been developing innovative solutions for a wide range of USB

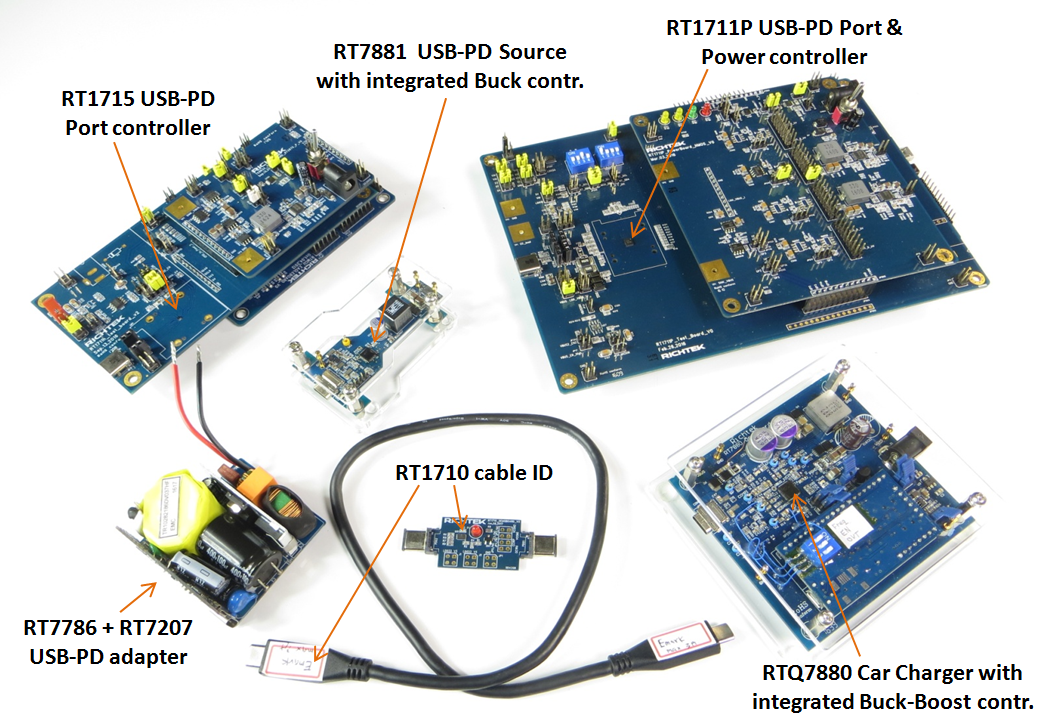

Type-C PD applications, from USB-PD power adapters, Car Chargers, Type-C cable e-Mark ICs to Type-C Dual Role Power PD port controllers which use the latest USB3.0 PD protocol to support Direct Charging systems. Figure 26 shows some

evaluation kits and development board for various USB Type-C Power Delivery

applications.

Figure 26

For USB Type-C Power Adapters with Power Delivery applications, we have developed RT7786 Flyback controller which works

together with RT7207 USB Type-C PD controller at secondary side. The wide

operation range of RT7786 and RT7207 make the output adjustable from 3 to

20V, and by using synchronous rectification via RT7207’s embedded

synchronous rectifier driver the rectifier losses at high output currents

are minimized.

RT1715 is a tiny (1.38 x 1.38mm CSP) but powerful

USB Type-C controller suitable for Sink or Source or Dual Role Power

Delivery applications. Supporting USB PD 3.0, VCONN power, Alternate Mode,

this IC can be used in a wide range of PD controller applications, like

Smart Phone, Hard drive or Tablet PC.

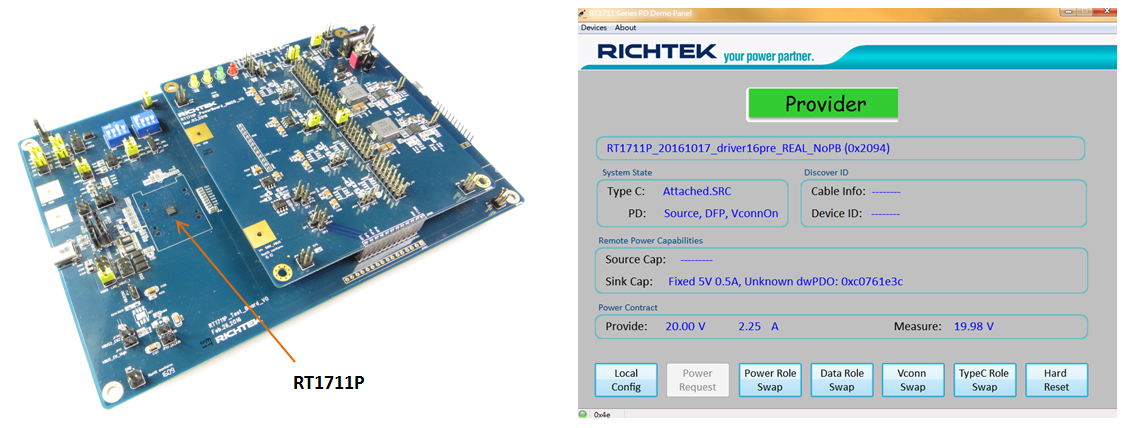

RT1711P is a full-featured USB Type-C controller

suitable for Sink or Source or Dual Role Power Delivery applications and

includes full dual role power path control, external DC converter output

voltage control, VBUS bleeder discharge and VBUS current sense. Supporting

USB PD 3.0, VCONN power, Alternate Mode this IC can be used in almost any

USB Type-C application with Power Delivery like Smart-Phone, Hard-drive,

Monitor, Notebook PC, Dongle or Car Charger.

RTQ7880 is an automotive grade USB Type-C PD Source

with integrated Buck-Boost controller. Its wide input voltage range in

combination with a Buck-Boost makes it suitable to be powered from Car

batteries and provide VBUS power from 5V/3A up to 20V/5A for charging any

USB-C device in a car environment. Supporting USB PD 3.0, VCONN power,

Alternate Mode and fully programmable cable drop compensation, this IC can

be used in wide range of USB Type-C Provider applications.

RT7881 is a USB Type-C PD Source with integrated

Buck controller for USB Type-C Provider applications. Having similar

features as RTQ7880, it can be used in wide range of USB Type-C Provider

applications that are powered from an input voltage that is higher than the

maximum required VBUS voltage.

RT1710 is a Cable ID (e-Mark) IC for passive and

active USB Type-C cables, like cables with 5A current capability or cables

with re-drivers for signal conditioning. RT1710 supports SOP’ communication,

and features embedded Ra / VCONN for both cable ends, isolation diode,

embedded MTP (multi-time rewritable memory for VDM data, with I2C

bus for writing VDM data and custom structured VDM writing through the CC

pin.

4. RT7786 & RT7207 Power Delivery Adapter

Conventional USB adapters for 5V only are relatively

straight-forward designs, as the output voltage is fixed and power levels

are relative low. But USB adapters with Power Delivery require that the

adapter output voltage can be varied over a wide range and they need to

provide higher power levels which can easily result in thermal issues in

small travel adapter form factors.

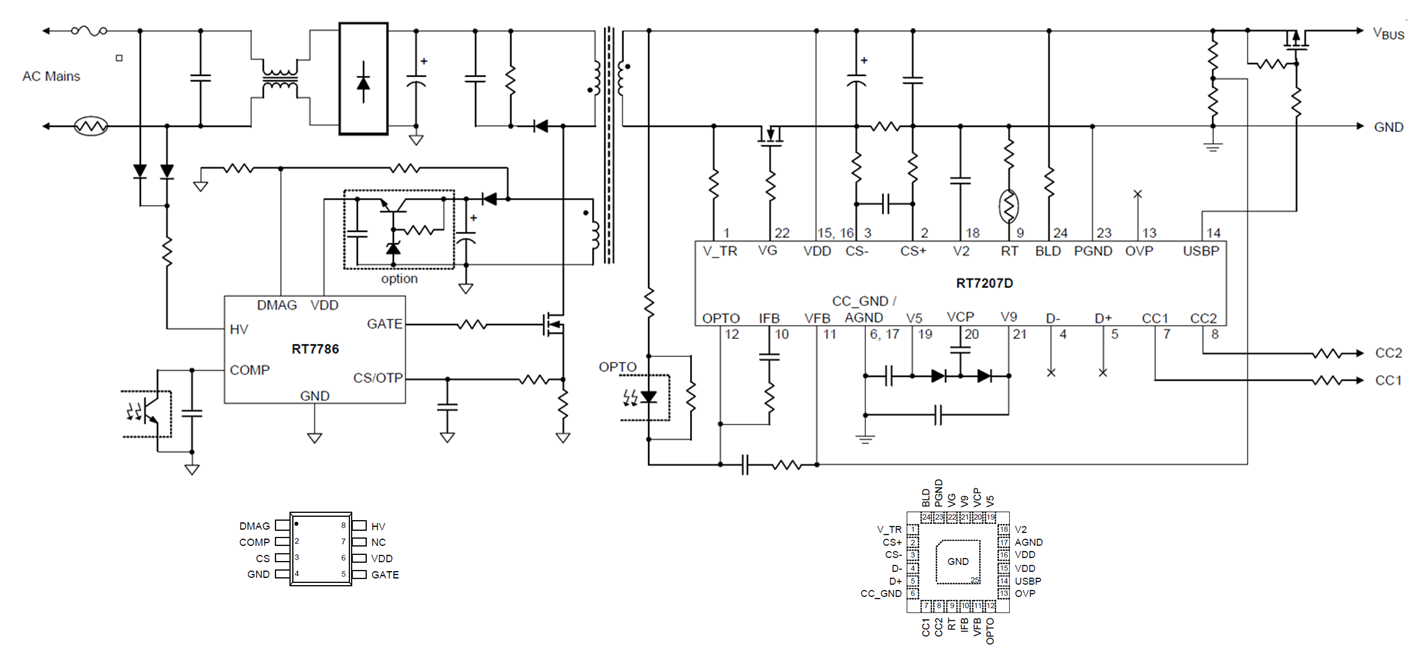

The Richtek RT7786 flyback controller is specially optimized for USB with Power Delivery : It can deliver a wide output voltage range, with adaptive loop gain control for maintaining stability, adaptive over-current and over-voltage protections, a wide VDD range allowing wider Vaux range, higher driver capability for driving large MOSFETs, has 30mW low power standby and SmartJitter for low EMI emission.

At secondary side RT7207 takes care of the flyback

converter output voltage control by controlling an opto-coupler based on

output voltage and current sensing. RT7207 also integrates an MCU to handle

the USB PD protocol, including BMC coding transceiver. The build-in charge

pump can ensure sufficient SR MOSFET gate drive even when output voltages

are below 4.5V. This allows output voltages down to 3.3V (3.0V for RT7207K)

allowing Programmable Power Supply (PPS) operation for Direct Charge

applications. The embedded driver for controlling a synchronous rectifier

can work in both DCM and CCM mode which increases the converter efficiency

at high loads. RT7207 has an OTP memory which allows programming of many

parameters, like over-current and over-temperature protections, and

programmable cable compensation. RT7207 can also be used in BC1.2 DCP

applications which make use of D+/D- pins for output voltage & current

setting. The basic schematic of an adapter using RT7786 and RT7207 is shown

in Figure 27.

Figure 27

A note about CC1/CC2 pin voltage rating: In the USB

Type-C connector, the CC1/CC2 pins are adjacent to the VBUS pins. Due to the

small pin pitch of the connector, there is a risk that during cable connect

or disconnect a short could occur between VBUS and CC1/CC2, resulting in

maximum 20V on the CC1/CC2 pins. Richtek USB-PD controllers like RT7207D

therefore have 22V voltage rating for the CC pins which make them more

robust.

Figure 28

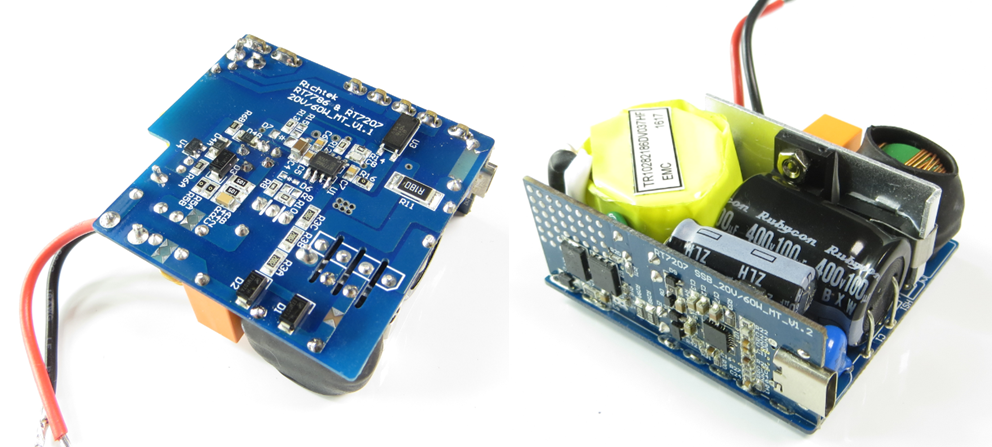

RT7786 + RT7207D reference design is available for

evaluation purposes. Figure 29 shows a 60W USB PD travel adapter design,

capable of delivering 5V, 9V, 15V and 20V at 3A from a full range mains

input.

Figure 29

The design dimensions are 53 x 50 x 23mm, has an

efficiency of over 93% at 60W output, achieves less than 50mW no-load

standby power and has been tested to pass USB IF compliance test, as well as

DOE-6 and CoC Tier-2 PSU efficiency requirements with good thermal results.

5. USB Type-C and Power Delivery in car charger

applications

USB Type-C only solutions

Currently USB Type-C connectors are gradually being

introduced in cars as well. Most car makers start with Type-C only,

providing 5V VBUS up to 3A. For these applications, a standard USB Type-C

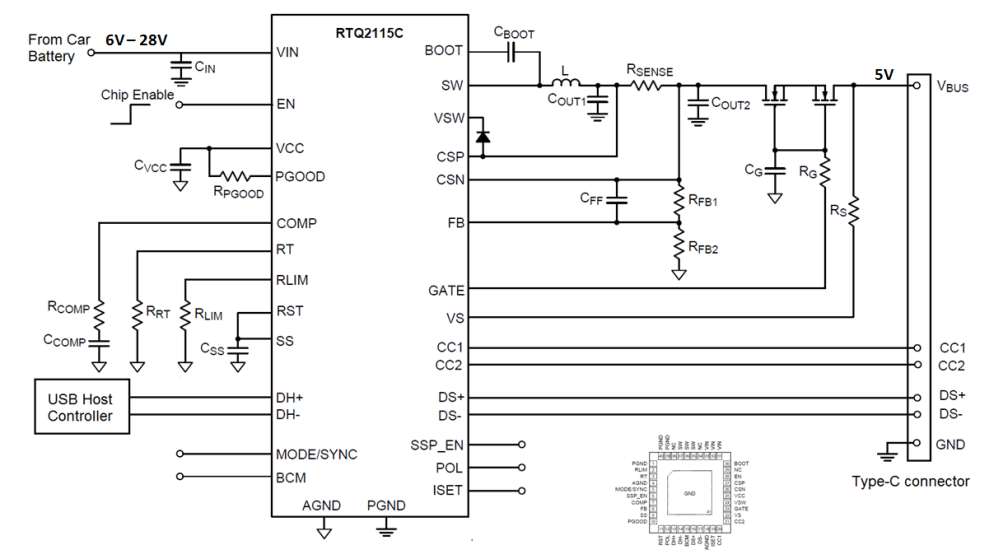

only controller with a Buck converter can be used. Figure 30 shows an

example of a Type-C only solution for car charger application.

|

Figure 30

|

RTQ2115C is an automotive grade Type-C

DFP controller + 3.5A buck converter with 3V to 36V input

voltage range. It includes CC line sensing and current

advertising, VBUS current sense and On/Off control, VCONN supply

control and cable polarity detection & output. It also includes

D+/D- sensing BC1.2 SDP/CDP/DCP modes and divider mode / 1.2V

mode detection.

|

USB Type-C car charger with Power Delivery

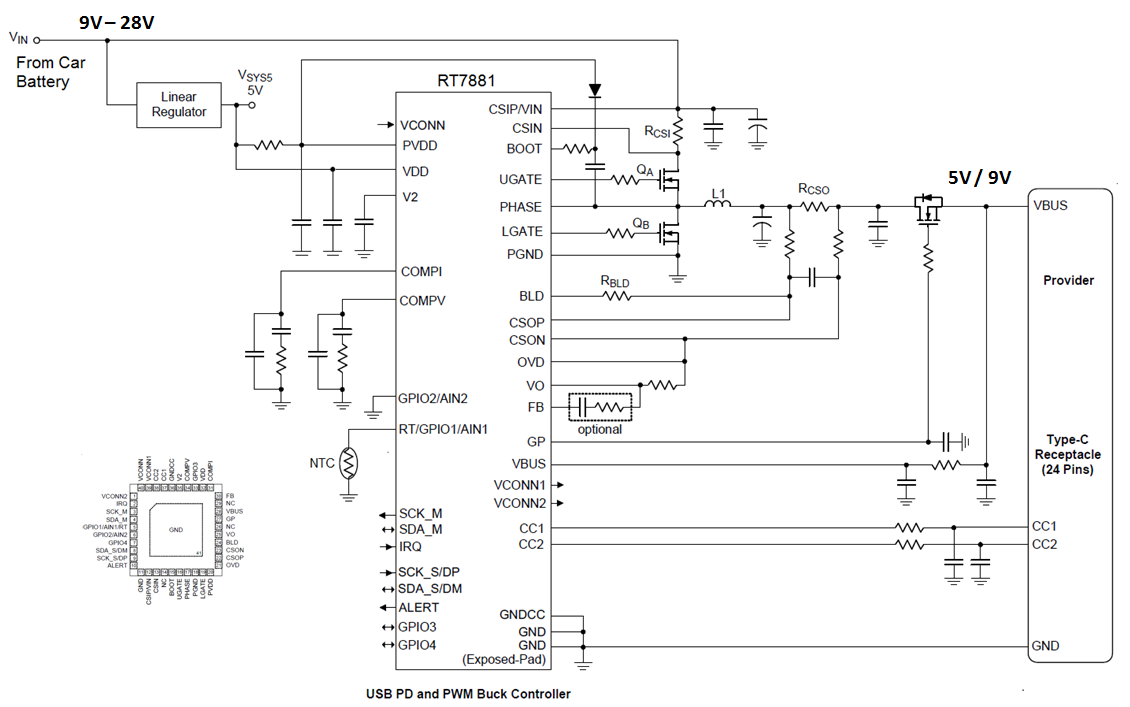

To implement USB Type-C with Power Delivery in car

systems, it depends on the battery input range and VBUS output range whether

a buck converter can still be used. In Power Delivery systems that only

require power profiles of 5V/3A and 9V/3A, a buck converter may still be

acceptable. In such systems, RT7881 may be used. RT7881 is a

USB Type-C PD Source with integrated Buck controller for USB Type-C Provider

applications. See Figure 31.

Figure 31

|

Figure 32

|

RT7881 integrates a Cortex M0 MCU which

controls all USB-PD communication, smart control of the

Buck-controller section including some firmware based

protections and customized functions.

Critical protections like VBUS OVP/USB

and OCP are all hard-ware based for fastest response. Output

voltage can be fine-tuned in 12mV/step, allowing digital cable

voltage drop compensation and Programmable Power Supply (PPS)

function.

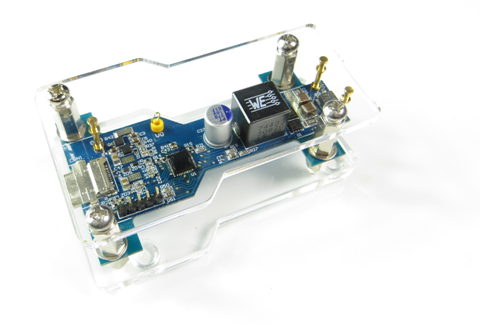

Figure 32 shows the RT7881 EVB in a

typical Car Charger form-factor.

|

USB Type-C car charger with Power Delivery full output voltage range

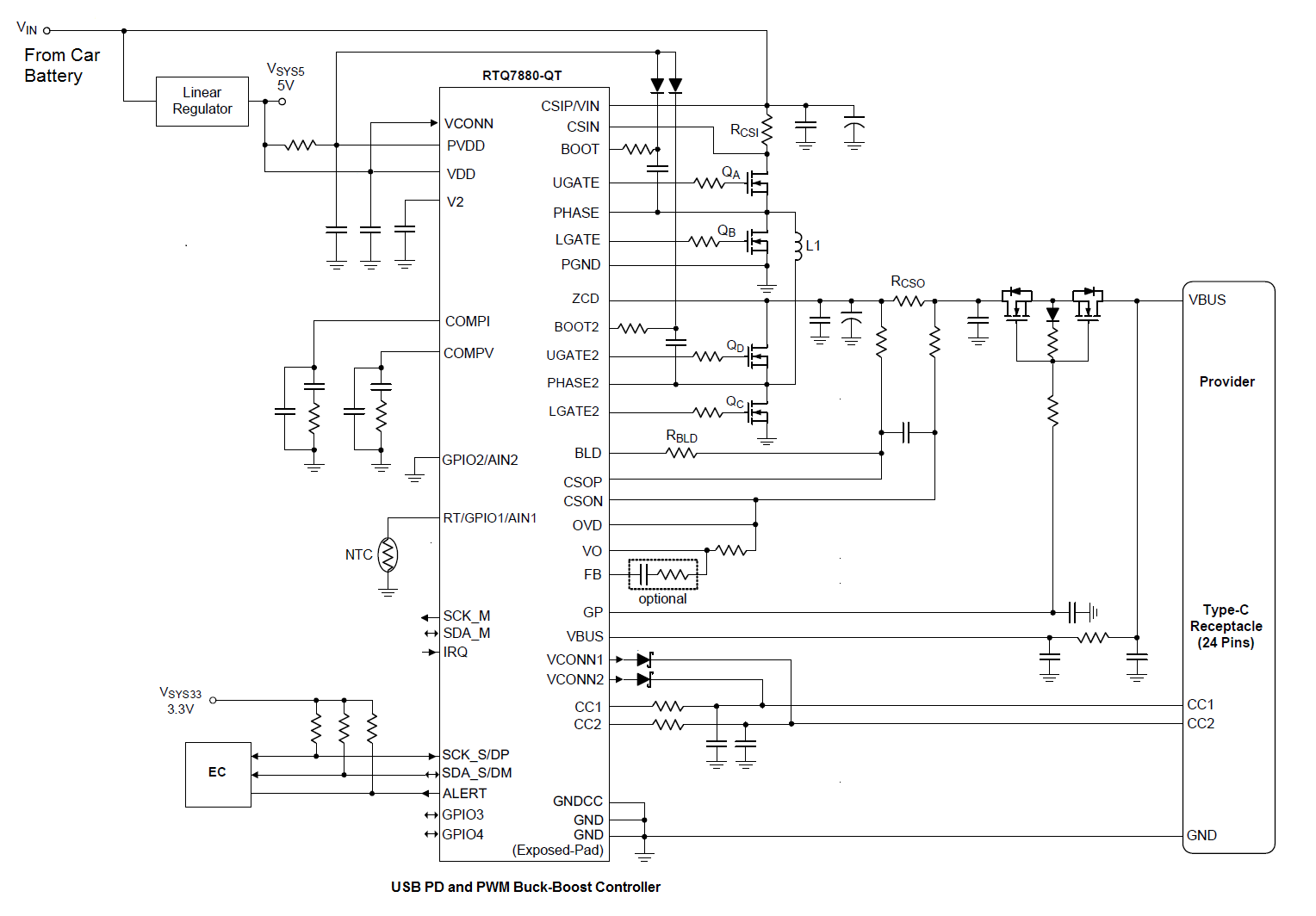

For car battery powered charger systems that need to

be able to supply the complete USB-PD output voltage range from 5V to 20V,

the power converter needs to be a buck-boost type. For these applications

Richtek has developed RTQ7880, an automotive grade USB Type-C PD Source with

integrated Buck-Boost controller for USB Type-C Provider applications. See

Figure 33.

Figure 33

The buck-boost converter consists of a full bridge.

In Buck mode, QA and QB are switching, and QD

is on, QC is off. In boost mode, QA is on, QB

is off and QC and QD are switching. The transition

from buck to boost mode is seamless.

Similar to RT7881, RTQ7880 includes a Cortex M0 MCU

which controls all USB-PD communication and smart control of the Buck-Boost

controller section.

The buck-boost controller is fully configurable,

with programmable switching frequency, current sense, force-PWM or PSM mode,

output voltage can be fine-tuned in 12mV/step, allowing digital cable voltage drop

compensation and Programmable Power Supply (PPS) function. RTQ7880 includes

a charge-pump for blocking MOSFET gate drive, allowing the use of cheaper

N-type blocking MOSFETs. CC1/CC2 lines are 20V tolerant, allowing CC line to

VBUS short-circuit. VCONN supply with current limit is included, for driving

systems with e-marked cables for output powers up to 100W (20V/5A).

|

Figure 34

|

RTQ7880 can be used as stand-alone

charger provider, but it can also be used in combination with an

Embedded Controller for added data communication with MUX.

Figure 34 shows the RTQ7880 evaluation

board which is capable of providing up to 60W (20V/3A) of output

power. The evaluation board includes a Richtek bridge board for

connection to a PC, to read the VBUS voltage and current status

and control PD functions.

The firmware of RTQ7880 is located in a

multiple programmable MTP memory. It can be re-flashed via the

Richtek bridge-board, but the IC can also be configured to be

programmable via the USB Type-C bus for firmware updating in the

field.

|

Besides car charger, RTQ7880 can also be used in

provider only applications like USB-PD display or hub. The buck-boost

converter makes it possible to power these systems from normal 12V input

power supply.

6. USB Type-C PD Dual Role Power (DRP) controllers

Previous USB applications used USB On-The-Go (OTG)

to be able to use the USB port for both charging and delivering power. In

USB type-C applications, Dual Role Power (DRP) controllers make it possible

to configure the type-C port as Source or Sink. DRP controllers need to be

able to switch the power path from source to sink and for Power Delivery

need to be able to configure the voltage regulator for the correct output

voltage. Richtek has developed a number of USB type C PD controllers with

DRP :

|

Part Number

|

PD version

|

Power Delivery

|

Dead Battery Support

|

20V CC line Protection

|

Power Path Control

|

VCONN Support

|

Package

|

|

RT1711H

|

USB-PD2.0

|

100W

|

Yes

|

Yes

|

No

|

Yes

|

CSP-9B 1.38x1.34

|

|

RT1716

|

USB-PD3.0

|

100W

|

Yes

|

Yes

|

No

|

No

|

CSP-8B 1.38x1.34

|

|

RT1715

|

USB-PD3.0

|

100W

|

Yes

|

Yes

|

No

|

Yes

|

CSP-9B 1.38x1.34

|

|

RT1711P

|

USB-PD3.0

|

100W

|

Yes

|

Yes

|

Yes

|

Yes

|

QFN-24L 3.5x3.5

|

All devices include the full type-C transceiver

including Rp and Rd resistors. In all cases, the Type-C controller will work

in combination with an Embedded system Controller (EC), which communicates

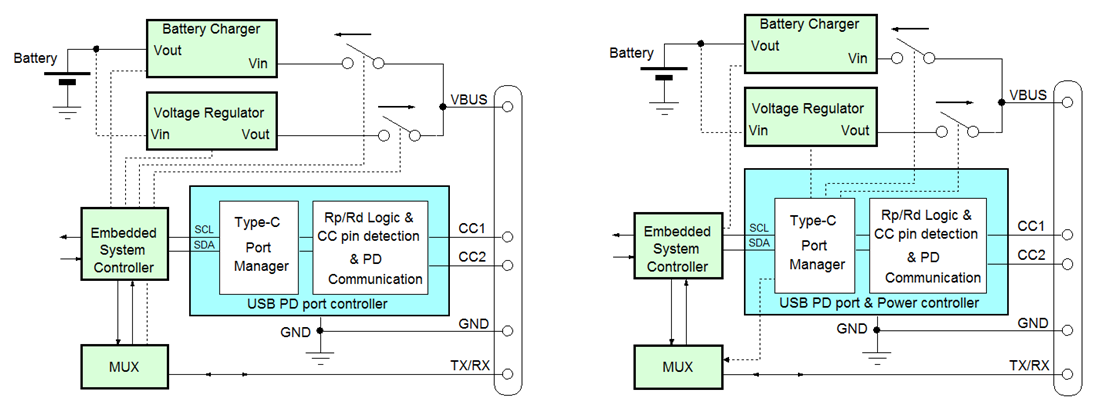

with the Type-C controller via I2C bus. Figure 35 shows two

possible ways to design a typical DRP solution like a Mobile Phone :

Figure 35

Figure 35 left side shows a DRP solution which makes

use of a USB Type-C PD port controller. The controller takes care of all

Type C port detection and communication and stores the information in

internal registers.

The embedded system controller will read the

registers and makes the decisions, activating MOSFET switches and

controlling voltage regulator for Source role or battery charger for Sink

role. In this case the USB PD port controller can be RT1711H, RT1715 or

RT1716.

Figure 35 right side shows a DRP solution which

makes use of a USB PD Port and Power controller. This controller includes

functions like external MOSFET control, voltage regulator control and data

MUX control. The embedded system controller still reads the registers and

makes the decisions regarding power role, but the commands are all send to

the PD power controller which activates the power path and control

functions. VBUS Protection functions like Bus over voltage and over current

can be executed immediately without EC intervention. In this case the USB PD

port controller can be RT1711P.

Since many DRP applications work with a battery, the

system has to be able to start-up when the battery is dead or has been

deeply discharged. Above mentioned controllers all support dead-battery

function, which means that even when no power is applied, the Type-C

controller will activate Rp resistors when the cable is connected, so a

Source will sense the pull-down action on the CC wire and activate the VBUS.

The Sink will then be able to wake-up the EC and the system can operate

without battery or try to recharge the battery.

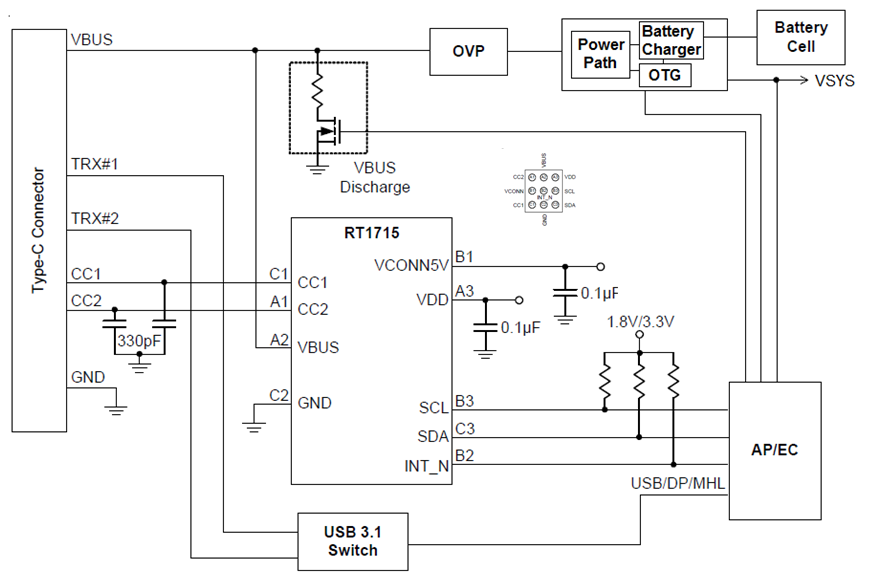

Figure 36 shows a typical application of a USB Type-C

DRP solution in a Smart-Phone using the Type-C PD controller RT1715, which

takes care of the CC line detection and communication and support for VCONN

to power e-marked cables.

|

Figure 36

|

The VBUS power control in this case is

handled by the embedded controller (EC) and a battery charger

like RT9466.

The EC reads the RT1715 registers, decides

the power role and sets the battery in charge mode (Sink role)

or OTG mode for Source role. The battery charger Power Path

control is used to switch on / off VBUS.

|

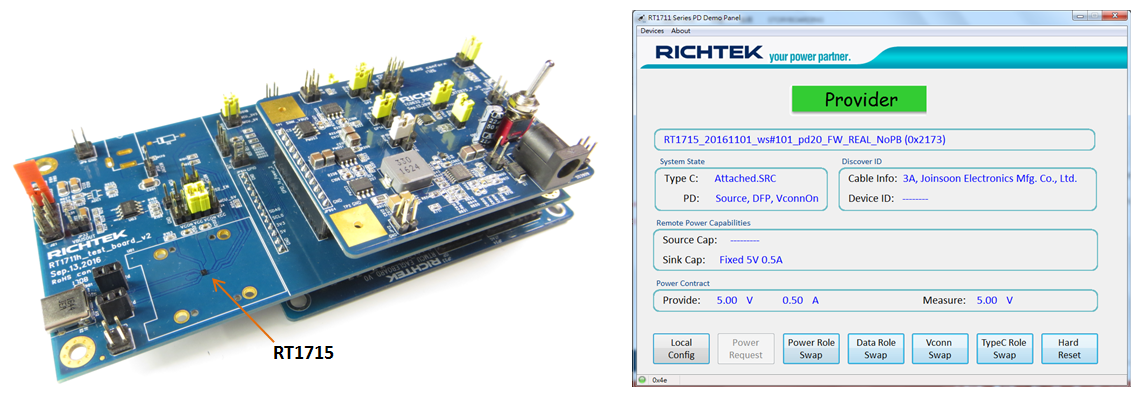

For development purpose, Richtek provides evaluation

boards for RT1711H, RT1715 and RT1716.

Figure 37 shows the evaluation board for RT1715, which

includes an embedded controller, voltage regulators, and switches for many

different hardware configurations. A GUI tool is provided which communicates

with the EC to read (via RT1715 registers) the USB Type-C port status, set

the power role and select various power profiles.

Figure 37

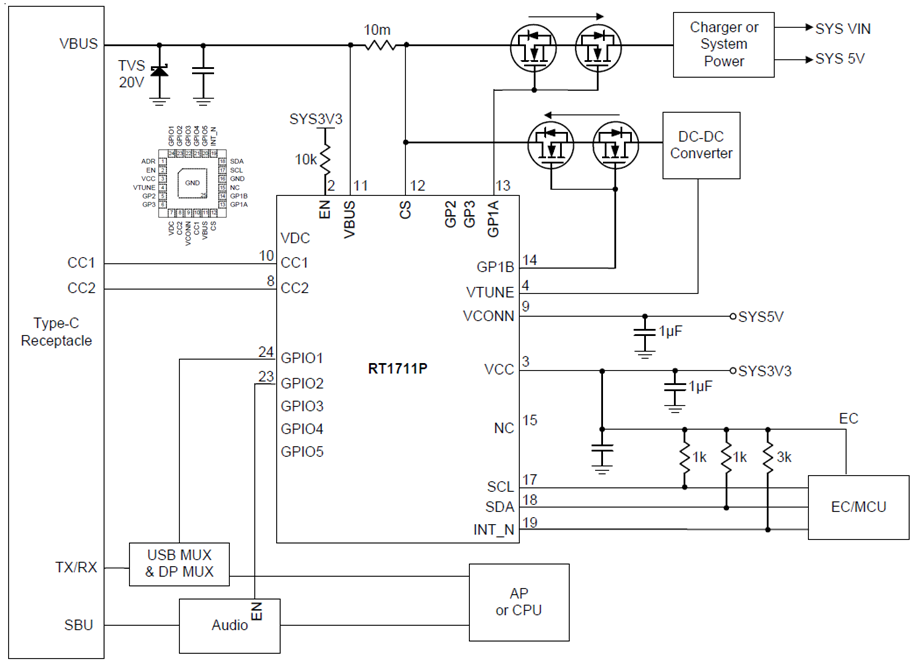

RT1711P is a full-feature USB Type-C controller

suitable for Sink or Source or Dual Role Power Delivery applications. Figure

38 shows RT1711P in a DRP application with full dual role power path

control, external DC converter output voltage control, VBUS over current and

overvoltage sensing and bleeder discharge. Supporting USB PD 3.0, VCONN

power and Alternate Mode, RT1711P can be used in almost any USB Type-C

application with power delivery like Smart-Phone, Hard-drive, Monitor,

Notebook PC, Dongle or Car Charger.

Figure 38

Also for RT1711P evaluation boards are available to

test the device in various configurations.

Figure 39 shows the evaluation board for RT1711P, which

includes an embedded controller, voltage regulators and switches for all

hardware configurations, with Power Delivery range from 5V/3A to 20V/3A. A

GUI tool is provided which communicates with the EC to read (via RT1711P

registers) the USB Type-C port status, set the power role and select various

power profiles.

Figure 39

7. Cable ID for USB type-C passive and active cables

USB Type-C Cables that support Superspeed USB3.1

data transfer or carry currents higher than 3A must be electronically

marked, which means the cable connector will include a small IC that

contains information about the cable properties, data performance, vendor

identification, etc. This e-mark IC will be powered by the VCONN line of the

Source, and transmits its data over the CC line. The e-mark IC will include

a Ra 1kΩ pull down resistor on the VCONN pin to let the Source know the

cable contains an e-mark IC. Once the cable is connected, BMC communication

will take place between Source and e-mark IC.

RT1710 is specially designed for providing a

flexible solution for electronically marked cables. It has two input supply

pins VCON1 and VCON2 with blocking diodes and embedded Rd resistors to allow

it to be powered from both cable ends as shown in Figure 40. The RT1710

communication supports USB Power Delivery Structured VDM Discover Identity

commands directed to SOP', and is fully certified to meet USB-IF

requirements. Its slew rate controlled BMC communication minimizes the EMI

effects.

Figure 40

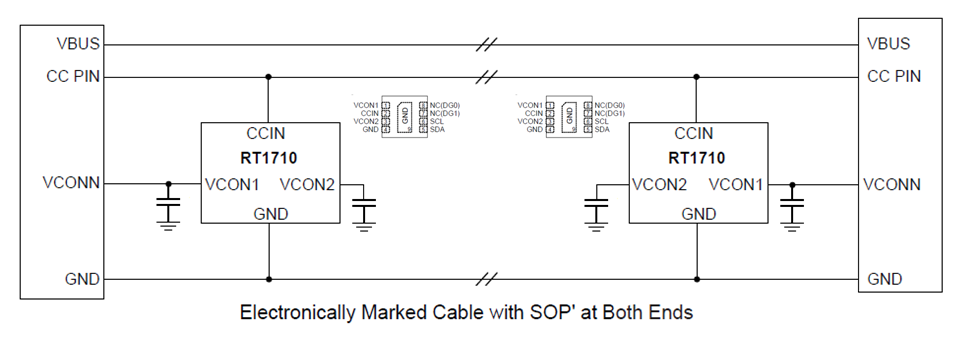

Although most cables will adopt the single IC

solution of Figure 40, some cable manufacturers may wish to place two ICs,

one in each connector, thereby reducing one wire in the cable. (See Figure

41). Each IC is now powered from the VCONN pin at each cable end. Since only

the Source will provide VCONN voltage, only one IC is active at the time.

Figure 41

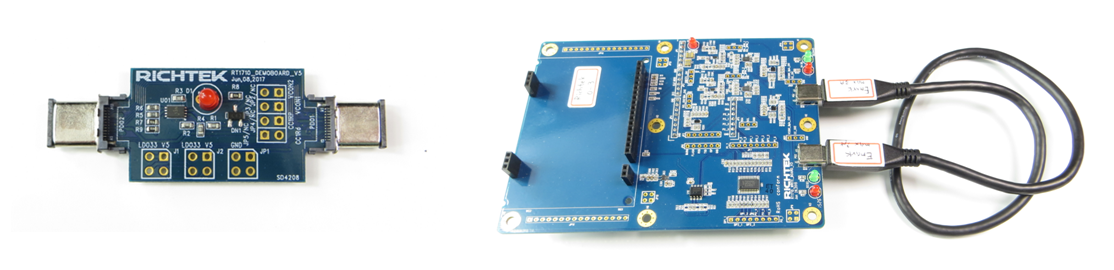

RT1710 has an embedded Multi-Time Programmable

memory for storing the VDM data. This data can be written into the MTP

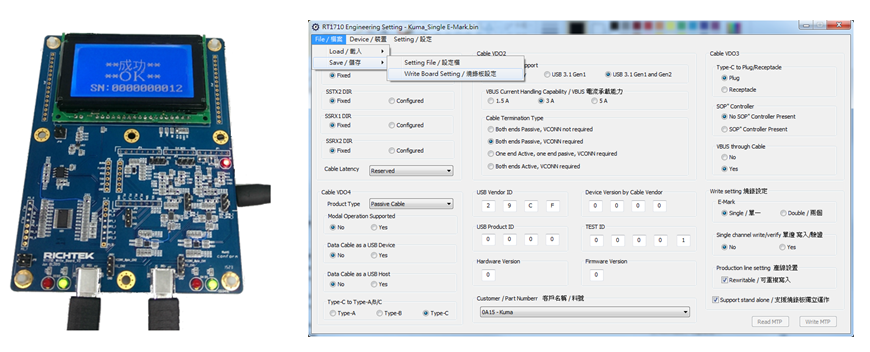

memory by using the Richtek programming tool. Figure 42 shows the RT1710

evaluation board and the programming tool.

Figure 42

For cable production and testing, the Richtek RT1710

production test kit and program can be used.

The test kit consists of a programming tool with LCD

display which is controlled a PC using the USB port.

Figure 43

The programming tool has two USB Type-C ports, and

can program and test cables with single or dual e-mark IC. The test kit will

be unique for each customer, with dedicated vendor ID. VDM data includes

cable serial number, which will be automatically updated each programming

cycle. The LCD screen will show the serial number and pass or fail message

for quality checking.

8. Summary

With the introduction of the USB Type-C standard,

a lot of new functionality is introduced. It is important to understand the

basics of the USB type-C Power Delivery standard and capability in

order to determine the application requirements.

Richtek is continuously expanding its power

management solutions for various USB Type-C with Power Delivery applications, from Type-C power adapter, Car charger, Display, Power Bank,

Cable ID to full function Dual Role Power applications like Smart Phones.